Garments Material behaves differently once it reaches the machine table. Fabric looks calm on the roll, everything changes once the needle starts moving. Cotton pulls softly, denim pushes back, lining fabric slips, stretch fabric reacts instantly. A tailor understands this difference within the first few stitches.

Daily work across Garments Material demands machines that respond without hesitation. Any delay, any vibration shows up on the seam line. Stitching loses balance when internal parts resist movement. That resistance comes from friction building quietly inside the machine.

How Machines Feel During Long Stitching Hours

A sewing machine talks through sound. Sharp noise means stress, dull vibration means friction. Tailors pick this up quickly. When lubrication stays consistent, machines sound calmer. Pedal response stays predictable. Needle movement feels steady under the foot.

Garment work rarely stays uniform through the day. One hour school uniforms, next hour alterations, later heavy ethnic wear. Machines must adapt without drama. That adaptation depends on internal movement staying free.

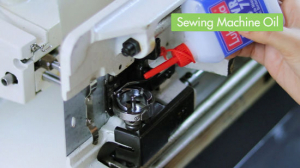

Tailor Machine Oil In Everyday Shop Reality

Tailor machine oil stays close to the worktable for a reason. Oiling remains part of the rhythm. A few drops before starting work, another round after lunch, light cleaning before closing. This habit keeps machines alive. Tailors working long shifts notice the difference immediately. Fabric feeds without drag. Corners stitch cleaner. Reverse stitching stays aligned. Even hand fatigue reduces when the machine stops fighting back. Lint builds fast during daily stitching. Thread dust settles inside moving joints. Clean oil pushes this out slowly. Machines feel lighter once oil reaches the hook area, needle bar joints, lower shaft.

Garments Material During Alteration Work

Alteration stitching tests machines more than straight production lines. Short seams, sudden stops, awkward angles. Machines face constant start-stop pressure. Without lubrication, this movement becomes rough.

Garments Material during alterations ranges from thin to layered within minutes. Oiling keeps transitions smooth. Needle penetration remains consistent across folded seams, waist adjustments, sleeve tightening.

Juki Machine Oil On Busy Factory Floors

Juki machines run hard. High speed, long hours, repeated cycles. Factories depend on them during peak orders. Internal balance matters more than anything else at that pace. Juki Machine Oil supports this pressure quietly. Hook timing stays stable. Shaft rotation feels controlled. Needle bars maintain rhythm even during extended runs. Light fabric stitching shows mistakes instantly. Oil clarity matters here. Proper lubrication avoids marks while internal movement remains protected. Production lines keep flowing without interruptions.

Production Speed Without Mechanical Stress

Speed alone does nothing without control. Juki machines handle speed well when lubrication remains steady. Heat stays contained. Bearings rotate freely. Alignment holds through long runs. Supervisors watch stitch consistency closely. A dry machine always shows early signs. Sound changes first, stitch spacing follows. Regular oil discipline avoids this chain reaction.

Jack Machine Oil Inside Modern Stitching Systems

Jack machines respond differently. Electronic control demands mechanical accuracy. Sensors rely on predictable movement. Any resistance throws timing off. Jack Machine Oil keeps this balance intact. Bearings move freely. Internal shafts rotate evenly. Automated functions execute without hesitation. Garment units handling sportswear, stretch garments, synthetic blends depend heavily on this stability. These fabrics react instantly to machine behavior. Lubrication keeps motion controlled during pattern shifts, speed variation, trimming cycles.

Precision Work Across Advanced Garments Material

Decorative stitching, logo placement, functional seams demand repeat accuracy. Jack machines perform consistently when internal friction stays low. Stitch definition remains clean across multiple cycles. Operators trust machines more when response stays predictable. Confidence improves workflow speed naturally.

How Silai Machine Oil Price Affects Workshop Planning

Silai machine oil price becomes part of monthly calculation. Small shops track usage carefully. Clear oil reduces cleaning time, lowers stain risk, keeps machines cleaner longer. Silai machine oil price varies with refinement level, packaging size. Workshops balance expense with performance through observation, not labels. Machines show the truth over time. Factories monitor silai machine oil price across bulk supply. Consistent lubrication saves maintenance downtime. That saving outweighs short-term cost thinking.

Long Days Demand Mechanical Care

Peak seasons stretch working hours. Machines run continuously. Heat builds quietly. Oil absorbs this stress. Regular oiling keeps parts aligned during extended sessions. Garments Material flows evenly when machine movement stays calm. Stitch rhythm remains steady. Noise stays low. Operators work longer without strain.