Introduction

The manufacturing industry is at a tipping point. Global competition, supply chain disruptions, and rising customer expectations have compelled enterprises to embrace smarter, more agile operations. One of the biggest catalysts for this transformation is Manufacturing Software—an integrated solution that unites business processes from procurement to production and distribution.

Today’s manufacturers are migrating from traditional on-premise setups to cloud-based ERP systems. These smart ERP solutions offer unmatched scalability, real-time insights, and operational efficiency. As a result, they play a critical role in digital transformation in manufacturing, enabling businesses to adapt faster, automate processes, and deliver more value with less waste.

The New Age of Manufacturing: What’s Driving the Shift?

Several forces are driving manufacturers to rethink their operational foundations. Global supply chain disruptions, such as those witnessed during the pandemic, have highlighted the need for real-time data and agile responses. In parallel, customer demand for personalization, faster delivery, and transparent processes is at an all-time high. Traditional ERP systems, often rigid and localized, fail to meet these modern requirements.

Cloud-based ERP systems resolve these pain points by offering scalable, accessible platforms that centralize data across multiple departments and geographies. Manufacturers can now access accurate insights from any location, reducing decision-making delays and eliminating information silos. Combined with pressure to reduce costs and increase efficiency, manufacturers are re-evaluating legacy systems and making the switch to smart, modern solutions.

In short, the shift is being driven by the urgent need for greater agility, innovation, and digital infrastructure that supports continuous adaptation and growth.

What Is Manufacturing ERP Software and Why It’s Critical Now?

Manufacturing Software is an integrated digital system that manages core manufacturing functions, including inventory, supply chain, production, procurement, finance, and compliance. Unlike general ERP systems, it is designed with manufacturing-specific workflows, providing real-time data and automation tailored to production environments.

ERP platforms unify these diverse functions into a single source of truth. This eliminates the redundancy, miscommunication, and delays that typically plague siloed systems. For example, when a change in sales demand occurs, it immediately reflects in procurement and production plans—enabling swift, informed adjustments.

Today’s advanced ERP solutions also align closely with factory automation software, IoT, and AI tools, creating a truly connected ecosystem. This level of integration allows manufacturers to embrace predictive analytics, respond to market changes in real-time, and maintain full visibility from the shop floor to executive dashboards.

In the era of Industry 4.0, a smart ERP is no longer just a business tool—it’s the digital infrastructure that powers resilient, efficient, and customer-centric manufacturing operations.

Cloud ERP for Manufacturing: The Engine of Smart Transformation

a. Real-Time Visibility Across Operations

Real-time visibility is one of the most powerful features of cloud ERP for manufacturing. These systems allow manufacturers to monitor everything from inventory levels to machine performance in real time. Managers can see where bottlenecks occur and adjust production on the fly. Instead of waiting hours or days for reports, decisions can be made instantly based on live data. This level of transparency leads to faster problem resolution, fewer delays, and better customer service. Visibility across operations also supports predictive analytics, helping businesses anticipate future issues rather than simply reacting to them.

b. Enhanced Scalability and Flexibility

Cloud-based ERP systems are inherently scalable. As your business grows, you can easily add new users, functions, or locations without major infrastructure investments. Whether you’re launching a new product line or expanding into international markets, cloud ERP adapts to your needs. Traditional on-premise systems often struggle with expansion—they require hardware upgrades, IT teams, and lengthy installations. In contrast, cloud ERP delivers updates seamlessly and supports remote teams and mobile access. For manufacturers facing constant change, flexibility is not a luxury—it’s a requirement.

c. Lower Total Cost of Ownership

One of the major advantages of moving to the cloud is the cost savings. With cloud ERP for manufacturing, there’s no need for expensive servers, maintenance staff, or physical infrastructure. Most cloud ERP solutions operate on a subscription model, allowing companies to pay only for what they use. This predictability improves budgeting and reduces capital expenditures. Additionally, automatic updates mean your system is always running the latest features and security patches, without requiring downtime or costly upgrades. Over time, cloud ERP proves more cost-efficient than legacy on-premise systems.

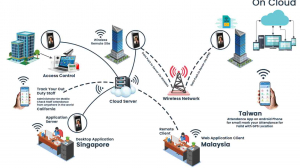

d. Increased Collaboration and Accessibility

Cloud ERP fosters real-time collaboration between teams, departments, and even external partners. Because it’s accessible from any device with an internet connection, staff in different locations can work together using the same data. This is particularly valuable for global manufacturers or those with multiple plants. Production teams, warehouse managers, and procurement officers can stay aligned without endless email threads or manual file transfers. Additionally, mobile-friendly ERP interfaces allow on-the-go access to key metrics, helping decision-makers stay connected and responsive at all times.

e. Robust Security and Compliance Features

Security is a top concern for any manufacturer, especially those handling sensitive customer data or operating under strict regulatory frameworks. Leading cloud-based ERP systems are built with advanced security features such as end-to-end encryption, role-based access, and multi-factor authentication. Compliance is also easier to manage with built-in reporting tools and automated audit trails. Whether you’re following ISO standards, FDA regulations, or GDPR mandates, a smart ERP solution can simplify compliance and reduce risk. Cloud ERP vendors also invest heavily in cybersecurity, making them more secure than many on-premise alternatives.

Benefits of ERP in Manufacturing: Tangible Business Outcomes

a. Reduced Downtime and Maintenance Costs

With predictive maintenance tools and real-time alerts, ERP systems help manufacturers reduce unplanned downtime. Integration with factory automation software enables monitoring of machine health, allowing teams to schedule maintenance before breakdowns occur. This proactive approach saves money and keeps production on schedule.

b. Improved Inventory and Supply Chain Management

ERP provides full visibility into raw material levels, supplier performance, and order statuses. Automated replenishment reduces stockouts, while real-time tracking minimizes excess inventory. This leads to lower carrying costs and higher efficiency across the supply chain.

c. Faster Time-to-Market

Manufacturing Software connects departments so product development, procurement, and production work in sync. This alignment accelerates the launch of new products, giving manufacturers a competitive edge. Shorter cycle times also mean quicker revenue generation.

d. Higher Customer Satisfaction

When your ERP system supports consistent quality, accurate order fulfillment, and on-time delivery, customers notice. A responsive, reliable operation builds trust and encourages repeat business. Real-time updates also improve communication with clients.

e. Better Compliance and Reporting

ERP platforms automate documentation and ensure accurate record-keeping. With pre-built compliance templates and dashboards, regulatory reporting becomes faster and less prone to human error. This lowers the risk of penalties and audit failures.

Future Outlook: Smart ERP as the Backbone of Industry 4.0

a. AI-Driven Decision Making

ERPs are becoming intelligent. With machine learning, they can auto-schedule production, optimize inventory, and detect anomalies without human input.

b. IoT & Sensor Integration

Live feeds from machinery allow ERPs to monitor performance, predict failures, and trigger alerts—bringing real-time intelligence to factory floors.

c. Hyper-Automation

Combining ERP with RPA (Robotic Process Automation) helps automate repetitive tasks like invoicing, order processing, and compliance tracking.

d. Sustainability Tracking:

Modern ERP systems can track carbon footprint, energy use, and waste output—supporting ESG goals and regulatory compliance.

e. Interoperability with New Tech Stacks

Future ERP platforms will offer greater interoperability with advanced analytics, AI, and customer-facing systems, creating a fully integrated digital enterprise.

Conclusion

The shift from traditional manufacturing systems to cloud-based ERP systems isn’t just a trend—it’s a necessity for survival and growth. Modern Manufacturing ERP Software empowers organizations to streamline operations, reduce costs, and build resilience.

By adopting smart ERP solutions, manufacturers can unlock real-time data insights, automate critical workflows, and position themselves for long-term success in a rapidly evolving industrial landscape.

If your factory floor still relies on legacy systems, now is the time to make the move to the cloud, to smarter systems, and a more agile, competitive future.