As global data traffic continues to surge, driven by cloud computing, 5G networks, hyperscale data centers, and fiber-to-the-x (FTTx) deployments, multi-fiber connectors have become a foundational component of modern optical communication systems. At the heart of their performance lies low-loss and high-precision alignment technologies, which directly determine signal integrity, network reliability, and scalability.

This article provides a comprehensive and objective analysis of low-loss & high-precision alignment technologies in multi-fiber connectors, integrating insights from multi-fiber connector market trends and forecast while examining tradeoffs, challenges, and decision-making impacts.

Understanding Multi-Fiber Connectors and Alignment Requirements

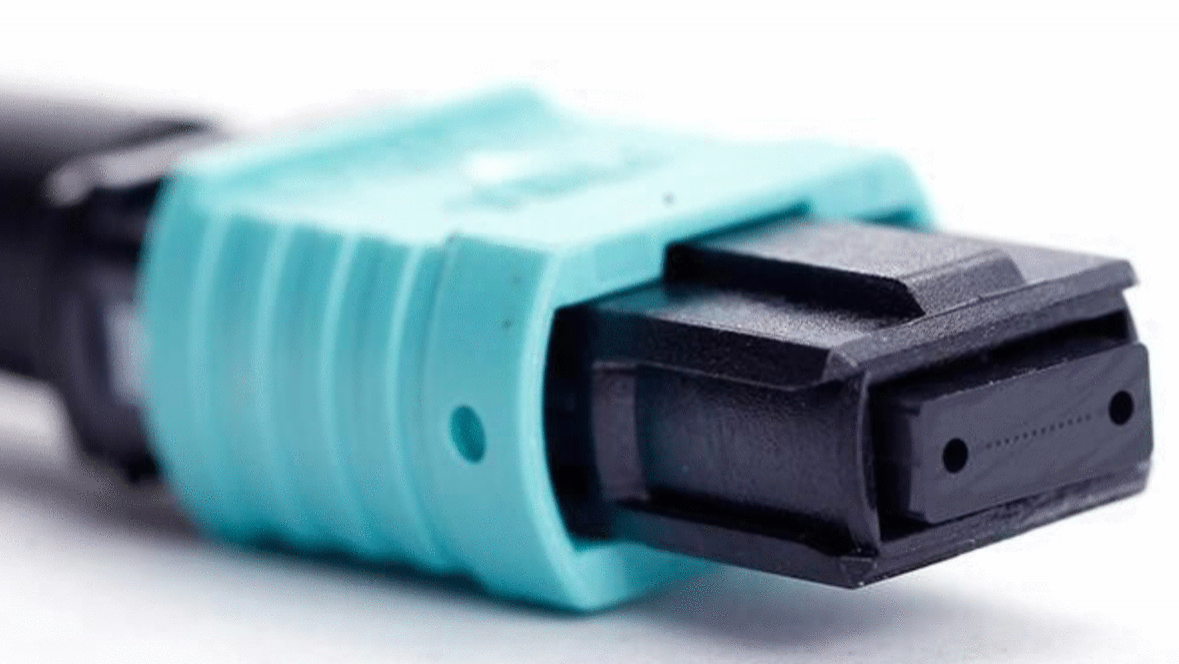

Multi-fiber connectors are designed to connect multiple optical fibers simultaneously, significantly increasing port density and reducing installation time compared to single-fiber connectors. Common examples include MPO (Multi-Fiber Push-On) and MTP connectors, widely used in data centers and telecom backbones.

Precise fiber alignment is critical because optical signals are highly sensitive to misalignment. Even micron-level deviations can cause insertion loss, return loss, and signal degradation. Low-loss performance ensures minimal attenuation, while high-precision alignment guarantees consistent connectivity across high-density fiber arrays.

Key Alignment Technologies Enabling Low-Loss Performance

Several alignment technologies are central to achieving low-loss performance in multi-fiber connectors:

1. Precision Guide Pin Systems

Metal guide pins and corresponding holes ensure accurate mating between connector ferrules. Tight manufacturing tolerances are essential to maintain consistent fiber-to-fiber alignment across repeated connections.

2. High-Accuracy Ferrule Materials

Ferrules made from thermoset epoxy, glass-filled polymers, or ceramic composites offer dimensional stability and low thermal expansion. Material selection directly affects long-term alignment reliability.

3. Advanced Polishing Techniques

Ultra-precision polishing of fiber end faces minimizes gaps, scratches, and angular deviations, reducing insertion and return loss.

4. Automated Assembly and Inspection

Robotics, machine vision, and interferometric inspection systems improve consistency, reduce human error, and support high-volume production.

Market Trends and Growth Outlook

According to multi-fiber connector market trends and forecast, the market is experiencing robust growth due to: Rapid expansion of hyperscale and edge data centers Increasing adoption of 400G and 800G optical transceivers Growth in 5G fronthaul and backhaul fiber infrastructure Rising demand for high-density, space-efficient connectivity

Tradeoffs in Alignment

Technology Design

Precision vs. Cost

Higher alignment precision typically requires tighter tolerances, advanced materials, and sophisticated manufacturing processes, increasing costs. Budget-sensitive deployments may accept slightly higher loss to reduce upfront expenses.

Density vs. Reliability

As fiber counts increase, maintaining uniform alignment across all fibers becomes more challenging. Higher density improves space efficiency but raises the risk of cumulative alignment errors.

Challenges Associated with Different Approaches

Manufacturing Tolerances: Achieving micron-level accuracy at scale remains technically demanding. Thermal and Mechanical Stress: Temperature fluctuations and repeated mating cycles can affect alignment stability. Contamination Sensitivity: Dust and debris can significantly increase loss in tightly aligned multi-fiber interfaces. Interoperability: Ensuring compatibility across vendors while maintaining alignment precision is an ongoing challenge. Addressing these issues requires continuous innovation in materials science, process control, and connector design.

Importance of Impact Considerations in Decision-Making

When selecting multi-fiber connectors, stakeholders must consider broader impacts beyond initial performance metrics: Network Efficiency: Low-loss connectors reduce power requirements for optical transceivers, lowering operational costs. Scalability: High-precision alignment supports future bandwidth upgrades without extensive re-cabling. Sustainability: Durable connectors with stable alignment reduce replacement frequency and material waste. Total Cost of Ownership: Higher upfront investment in precision technologies can result in long-term savings through reduced maintenance and downtime.

Complete Industry Breakdown

Material Suppliers: Provide ferrule and guide pin materials with tight dimensional control Connector Manufacturers: Design and produce multi-fiber connectors and alignment systems Equipment OEMs: Integrate connectors into transceivers, switches, and patch panels Data Center & Telecom Operators: Drive demand through bandwidth and density requirements Standards Organizations: Define performance benchmarks and interoperability guidelines

Low-loss and high-precision alignment technologies are fundamental to the performance and scalability of modern optical networks. As highlighted by multi-fiber connector market trends and forecast, growing data demands and higher transmission speeds are intensifying the need for accurate, reliable, and cost-effective alignment solutions. By understanding the tradeoffs, challenges, and broader impacts involved, stakeholders can make informed decisions that support both current performance requirements and future network evolution.