Introduction

Growing Need for Tyre Recycling in India The automobile, logistics, and infrastructure industries in India are creating millions of end-of-life tyres each year, which can pose significant environmental and fire hazards if not disposed of correctly. Due to all these factors, there are great opportunities to establish tyre recycling companies in India, particularly as many entrepreneurs are beginning to see that it is a huge potential market and a sustainable and profitable business venture.

With all the various government initiatives focused on promoting the circular economy and regulated producer responsibility (RPR), as well as sustainable waste management, starting a tyre recycling company in India is no longer considered an alternative; rather, it is being recognized as an internally regulated and fast-growing industry.

Furthermore, this blog discusses the Tyre Recycling Process, market opportunities, tyre recycling plant in India, plant setup requirements, compliance requirements, and business viability, enabling investors and entrepreneurs to make informed choices about their business prospects in this industry.

Tyre Recycling Market in India Is on the Rise

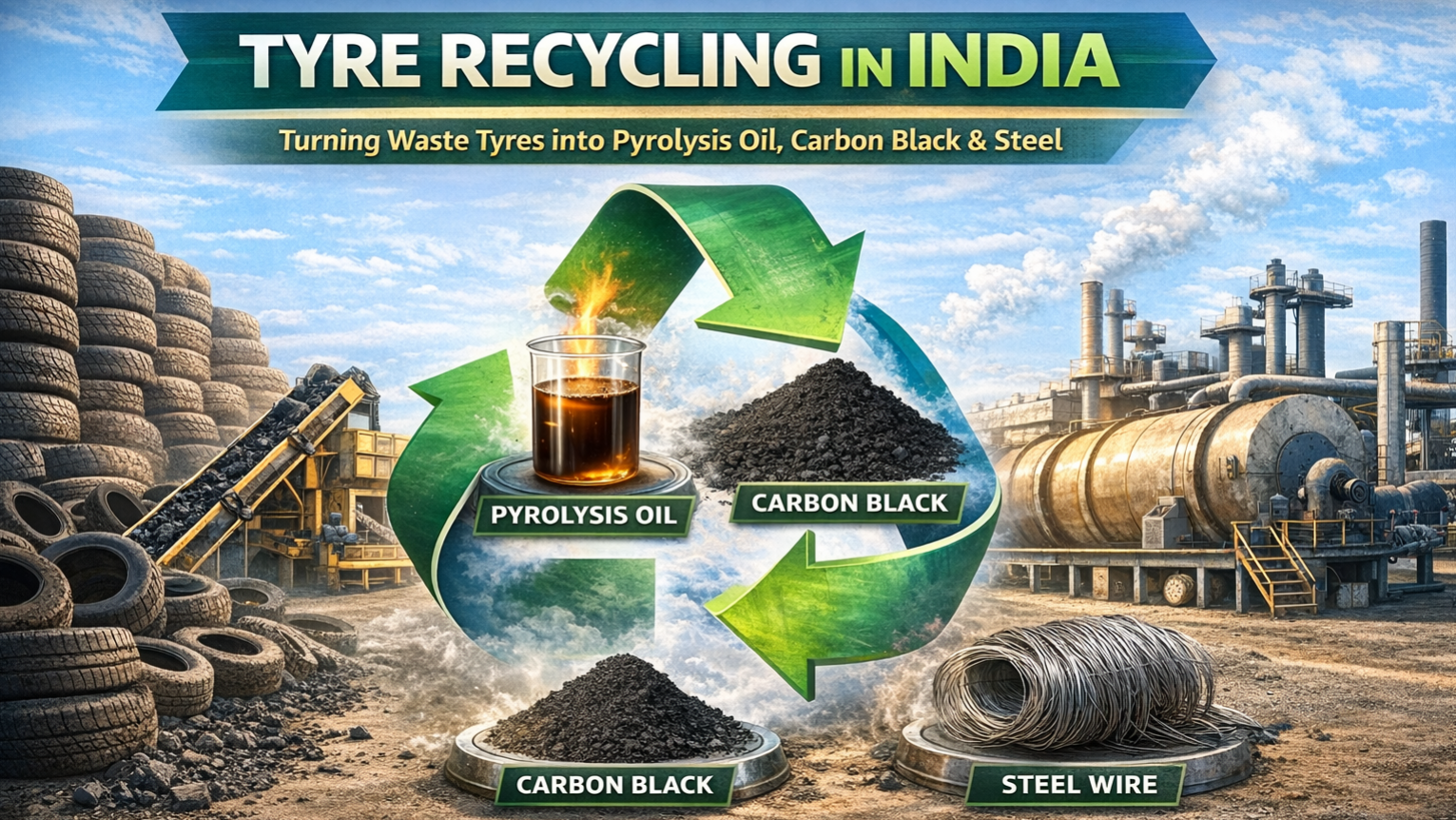

There are many tyre recyclers in India engaged in the recycling of used tyres, converting them into useful items such as crumb rubber, pyrolysis oil, steel wires, and carbon black. Moreover, with the increase in the number of vehicles on Indian roads, providing consistent sources for used tyres, the recycling tyres business is expected to be viable and profitable for a long time into the future.

A professionally run tyre recycling company that adheres to strict environmental norms recycles waste tyres into value-added products, thereby reducing landfill pressure and environmental pollution. As demand from the construction, road development, and manufacturing industries continues to rise, tyre recycling is becoming an indispensable part of India's green economy.

Besides that, several well-established tyre recycling companies in India are now enlarging their businesses due to policy support, EPR obligations, and the increasing awareness of and need for proper waste disposal.

What Is a Waste Tyre Recycling Plant?

A waste tyre recycling plant is a facility where old, damaged, or discarded tyres are processed and converted into reusable raw materials using mechanical, thermal, or chemical methods.

The frequently used technologies are: Mechanical shredding and granulation Pyrolysis process Devulcanization Crumb rubber production

A technologically advanced waste tyre recycling plant in India not only helps to alleviate the negative consequences for the environment, but it also opens up numerous options for income generation from just one source of waste.

Tyre Recycling Plant Cost in India

One of the most frequently asked investor questions is about tyre recycling plant cost in India, which can vary significantly based on: Plant size (MT/Day or metric tons per day) Technology being used (Shredding technology or pyrolysis) Quality of machinery purchased Land and infrastructure requirements Pollution control systems required

For the most part, tyre recycling plant cost in India typically ranges between ₹50 lakhs for a smaller facility and several crores for large-scale, fully automated plants. Although the initial investment can often seem daunting, the margins associated with the recycling tyres business and the ready availability of raw materials make this an economically sensible investment opportunity.

Tyre Recycling Business Opportunities

In the recycling tyres business, there are multiple ways to monetise, including selling crumb rubber, fuel oil, recovered carbon black, and scrap steel.

In addition to the above, the old tyre scrap business plays a crucial role in the supply chain, where collectors and aggregators supply waste tyres to authorised recyclers, ensuring uninterrupted raw material availability for tyre recycling plants.

Due to government incentives and ESG compliance requirements, tyre recycling business ideas focusing on sustainability and efficiency are gaining strong momentum across India.

Innovative Tyre Recycling Business Ideas

Modern entrepreneurs are exploring tyre recycling business ideas such as manufacturing rubberised asphalt, playground flooring, sports tracks, and eco-friendly construction materials. These advanced business models help tyre recycling companies in India move up the value chain while supporting sustainable infrastructure development.

Legal & Environmental Compliance in India

A tyre recycling plant installation is subject to approvals from: Central & State Pollution Control Boards (CPCB/SPCB) Environmental Clearance (if applicable) Consent to Establish & Operate EPR Registration for waste tyre recycling plant Factory License Fire Safety Approval

Non-compliance can severely impact tyre recycling companies in India, making professional support essential.

Corpseed offers end-to-end consultancy services for setting up a waste tyre recycling plant in India, including approvals, EPR registration, and compliance management.

Why Take Help from Professionals?

Many tyre recycling companies in India fail due to improper planning, technology selection errors, and regulatory non-compliance. Professional consultants help ensure: Cost optimisation for tyre recycling plant setup Selection of suitable recycling technology Faster approvals Long-term compliance support.

Future Outlook of Tyre Recycling in India

The future of tyre recycling companies in India looks promising due to mandatory EPR implementation, rising automobile production, infrastructure growth, and increased demand for recycled rubber products.