The Role of Automation in Aluminium Extrusion Machinery (2)

0 likes | 5 Vues

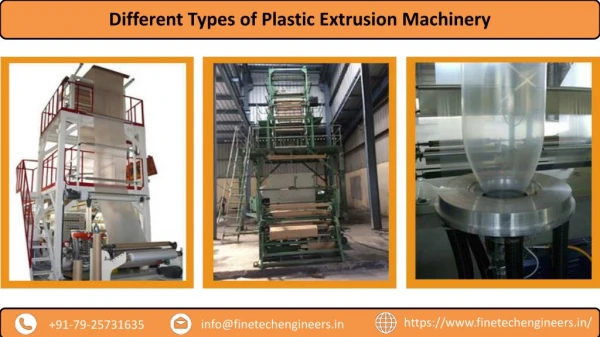

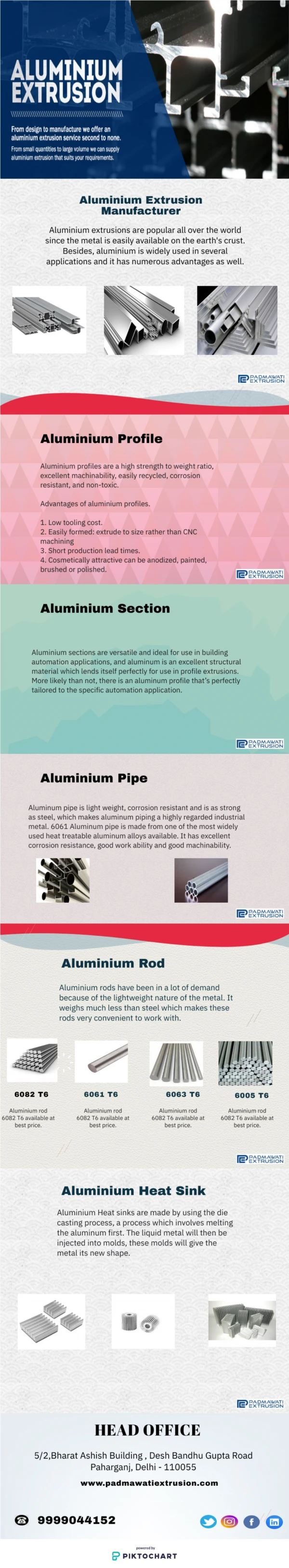

Automation in aluminium extrusion machinery integrates servo-driven presses, robotic billet loaders, and PLC-controlled handling systems to optimize efficiency and precision. Automated die changers, power pushers, and conveyorized cooling tables enhance throughput while reducing downtime. Smart monitoring systems with IoT connectivity enable predictive maintenance, minimizing failures. Heavy-duty cantilever racks streamline profile storage, ensuring seamless logistics. These advancements enhance extrusion speed, consistency, and energy efficiency in high-volume manufacturing environments.

Télécharger la présentation

The Role of Automation in Aluminium Extrusion Machinery (2)

An Image/Link below is provided (as is) to download presentation

Download Policy: Content on the Website is provided to you AS IS for your information and personal use and may not be sold / licensed / shared on other websites without getting consent from its author.

Content is provided to you AS IS for your information and personal use only.

Download presentation by click this link.

While downloading, if for some reason you are not able to download a presentation, the publisher may have deleted the file from their server.

During download, if you can't get a presentation, the file might be deleted by the publisher.

E N D

Presentation Transcript

More Related